Newamstar Automatic Pet Bottle Filling Machine

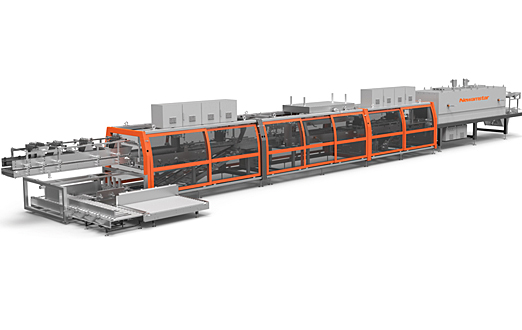

Newamstar High-speed Blowing-filing-capping Combibloc combines the blowing, filing and capping system reducing transmission, empty bottle handling, storage processes, which improved packaging hygienic condition and reduce packaging cross-contamination so as to improve the overall operating efficiency but lower the energy consumption, thereby reduce the overall production cost of enterprises.

Product Description:

· Products can be handled

Pure water, mineral water, spring water, etc.

· Containers can be handled

PET bottles with different volumes and shapes

· Filling system

Gravity filling

· Capacity

5000BPH-80000BPH

· Main composition

3-in-1 monobloc is composed of rinser, filler, capper, machine base, covering windowns, main motor and transmission system, cap unscrambler and electric control system, etc.

The overturning device of the rinser is mainly composed of water distributor, bottle gripper, upper rotary tray, guide trackl, protection cover, water spraying device and water collection tray.

Filling device is mainly composed of filling barrel, filling valve, guide rail, elevating device, elevating device, etc.

Capping device is composed of cap unscramblerr, cap falling chute and capper.

The auxiliary (or optional) equipment include rinsing water recycle tank, bottle-in air conveyor and bottle-out conveyor. In addition, the manual bottle feeding table (or bottle unscrambler) and automatic cap elevator can be equipped according to customer requirement.

| Item | Remark | Capacity | |

| Water Treatment System | 5-100T/H | ||

| Beverage Pre-treatment System | 5-60T/H | ||

| Filling production line | Aseptic Filling Line | PET Bottle | 12000-43200BPH |

| Blowing-Filling-Capping Combiblock | PET Bottle | 12000-80000BPH | |

| Rotary Blow Molding Machine | PET Bottle | 12000-80000BPH | |

| Hot Filling Line | PET Bottle | 12000-43200BPH | |

| Ultra-clean (Middle Temperature) Filling Line | PET Bottle | 12000-43200BPH | |

| Ultra-clean (ESL) Filling Line | PET Bottle | 12000-43200BPH | |

| Bottled Water Filling Line | PET Bottle | 12000-80000BPH | |

| 3L-10L Big Bottle Water Filling Line | PET Bottle | 16000-6000BPH | |

| 5L Big Bottle Water Blowing-Filling-Capping Combiblock | PET Bottle | 2000-12000BPH | |

| CSD Filling Line | PET Bottle | 12000-43200BPH | |

| CSD Filling Line | Glass Bottle | 12000-43200BPH | |

| CSD Filling Line | Can | 9000-30000BPH | |

| Condiment (Soy sauce, Vinegar) Filling Line | PET Bottle | 5000-36000BPH | |

| Condiment (Soy sauce, Vinegar) Filling Line | Glass Bottle | 5000-36000BPH | |

| 3L-5L Big bottle Edible Oil Filling Line | PET Bottle | 1000-6000BPH | |

| Liquid Household & Personal Care Products Filling Line | PET Bottle | 5000-36000BPH | |

| Beer Filling Line | PET Bottle | 12000-48000 BPH | |

| Barreled Water Filling Line | 3/5 Gallon | 600-3000BPH | |

| Downstream Packaging (PE Film Shrink Wrapper, Packer, Palletizer, etc.) System | 5000-80000BPH | ||

| Shuttle-type automatic warehouse system | |||

| Stacking-type automatic warehouse system | |||

| Management system of intelligent factory | |||